KUPO

KUPO series

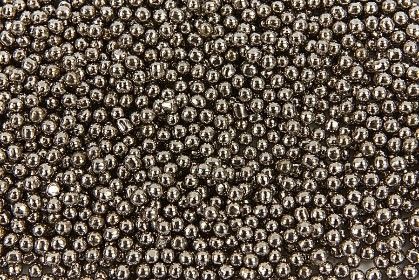

KUPO series ball burnishing machines produce high-gloss surfaces on your components.

Thanks to the axial vibration by means of two synchronised drive motors, the process time is reduced and high throughput rates can be realised. The adjustable vibration packages are positioned on the respective axis of rotation. Shiny and flawless workpieces are achieved. optimum work bowl geometry.

Ball burnishing machines series KUPO are suitable for economic ball or satellite burnishing for small and large workpieces made of e.g. steel, stainless steel and light alloys etc.

Ball burnishing

Satellite polishing

The work tank with optimal work bowl geometry consists of a heat-treated sheet steel construction with PU lining. Two axial unbalance packs are connected to the motors (3000 RPM) by tension couplings. The intensity can be adjusted by regulating the eccentric masses. The machine is enclosed with soundproof cladding.

Frame sizes

-

Gross volume:

65 – 970 litres

-

Useful volume:

50 – 860 litres

-

Drive capacities:

2 x 2,2 – 5,5 KW*

-

Speed:

3.000 R/min

-

Connector:

400 V / 50 Hz; CEE Connector*

-

* Depending on the machine size and customer application.

Equipment

-

PU lining

Control types

-

- Control with push-button and digital timer as well as operating hours counter

-

- Control with touch panel and MINI-PLC

-

- PLC control Siemens S7 - customer-specific

Container cross-sections

Options

-

Separation bulkheads that can be fixed in different positions

-

Frequency converter for weight speed control

-

Soundproof cabin with manual/automatic opening

GOOD TO KNOW

Economical rim polishing by polishing with stainless steel balls (polishing time approx. 60 min.). Specially stiffened machine for filling 3,400 kg stainless steel balls. Shiny rims thanks to the optimal geometry of the polishing tank.

Rims after rim polishing

Rim polishing by polishing with stainless steel balls.