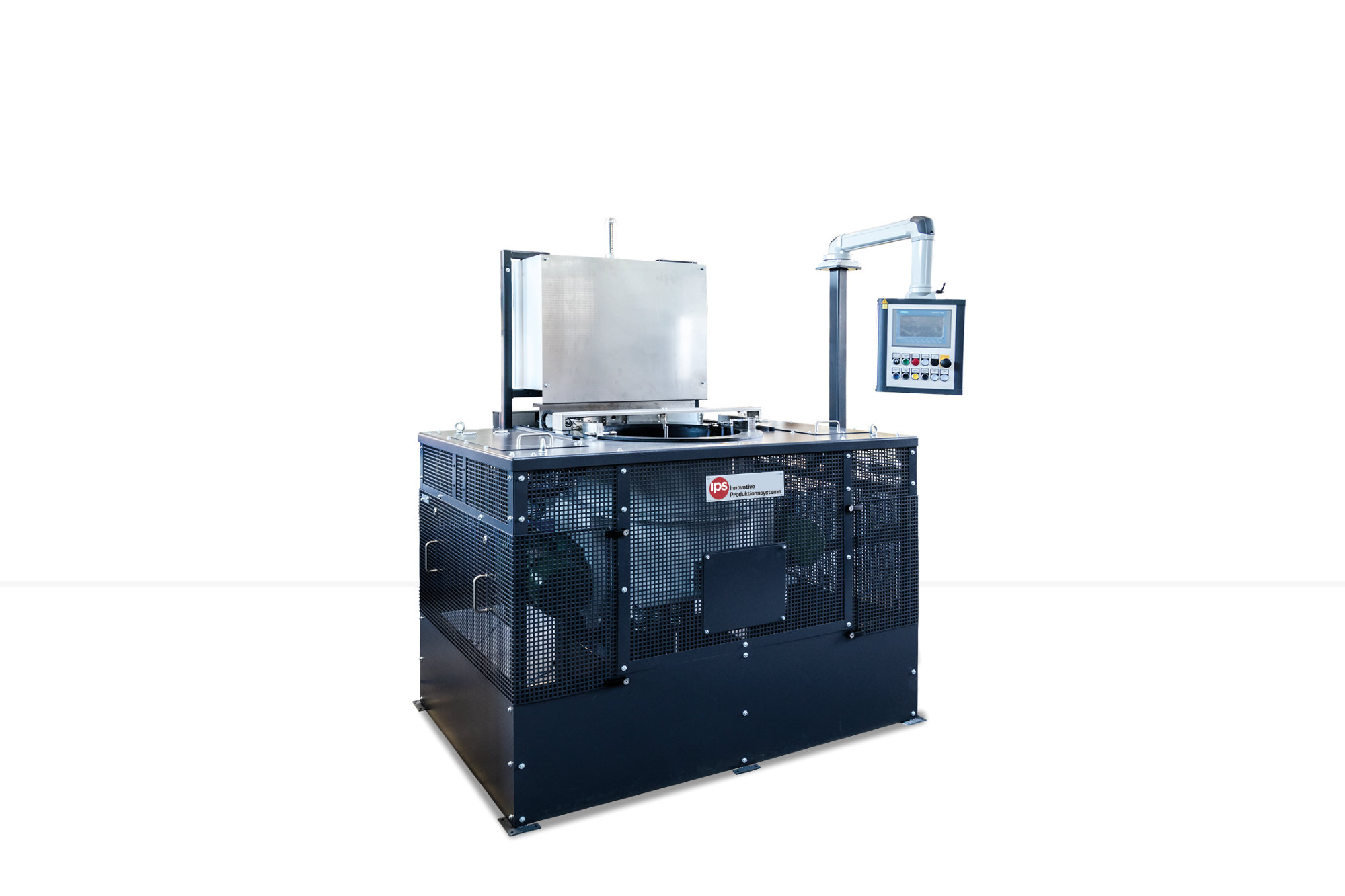

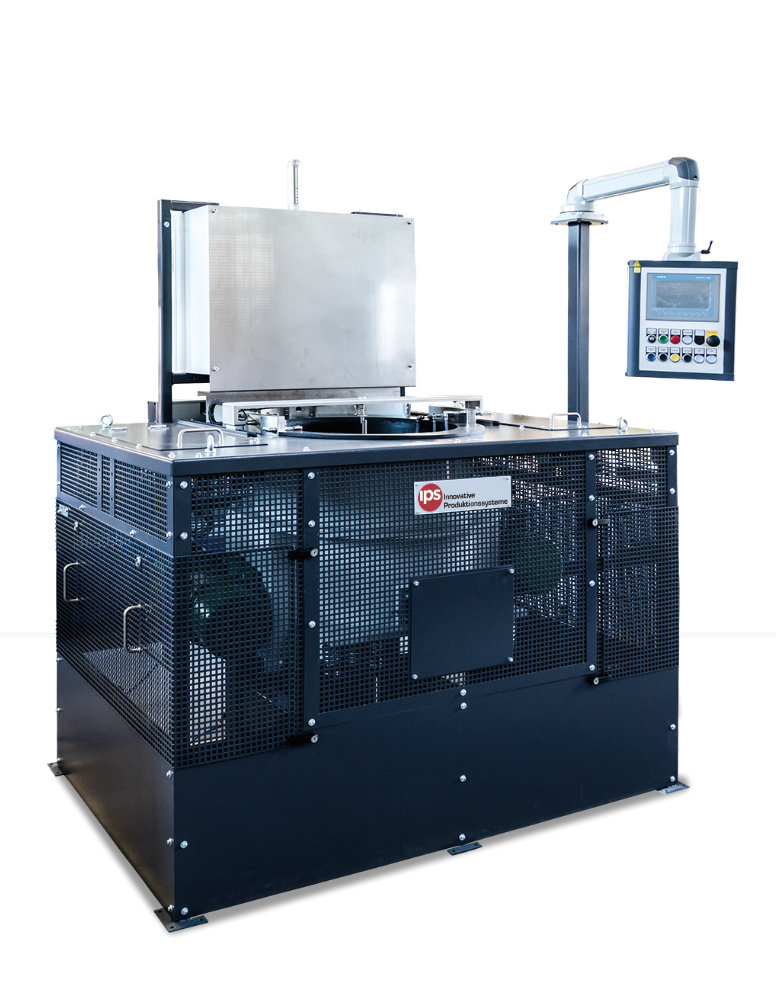

PREMIUM

PREMIUM series

The PREMIUM series is characterised by a pneumatically extendable central mandrel on which the workpiece is mechanically fixed. This significantly simplifies loading and unloading. Emptying the container for loading and unloading components is no longer necessary and thus saves valuable process time.

Frame sizes

-

Container heights:

400 / 500 / 600 mm

-

Diameter:

22“ till 50“ (560 – 1.270 mm)

-

Drive capacities:

2 x 0,55 – 5,5 KW*

-

Speed:

1.500 – 3.000 R/min*

-

Connector:

400 V / 50 Hz; CEE connector*

-

*Depending on the machine size and customer application.

Equipment

-

Base frame with adjustable machine feet

-

Working container made of sheet steel - welded construction

-

Two vibration motors with high adjustable centrifugal forces

-

Dosing system for compound

Control types

-

- PLC control Siemens S7 - customer-specific

Options

-

Magnetic chucks

-

Conversion kit fixed centre spike

-

Conversion kit movable centre mandrel

-

Integrated lifting station with pump for process water recovery

-

Sound insulation lid

-

Sound insulation enclosure

-

Granulate level monitoring

-

Container temperature control

-

Part separation (customer-specific)

-

FlexAngle - Adjust motor position individually

-

Automatic clamping system

-

Customised clamping systems

-

Integration in automated production line (Smart Factory) possible

-

Funnel with scraper brush

-

Granulate level monitoring

Good to know – FlexAngle

With its flexibly adjustable motor positions, the PREMIUM - "FlexAngle" series is the ideal solution for achieving an extremely precise surface result.

FlexAngle

Positive and non-positive motor position

Individual setting

Adjustable in 2° steps